MANUFACTURING PLANNING & OPTIMIZATION

Manufacturing Operating Systems (MOS)

OES designs new or optimizes existing manufacturing systems. We approach manufacturing processes with a focus on Quality, Throughout, and Total System Lean Principles. OES focuses on enhancing the efficiency of manufacturing systems to reduce the time to launch your product, shorten product time in the manufacturing system, reduce Work in Process (WIP), and minimize or eliminate manufacturing/assembly change-over times. OES can implement flexible assembly processes for products with high option content.

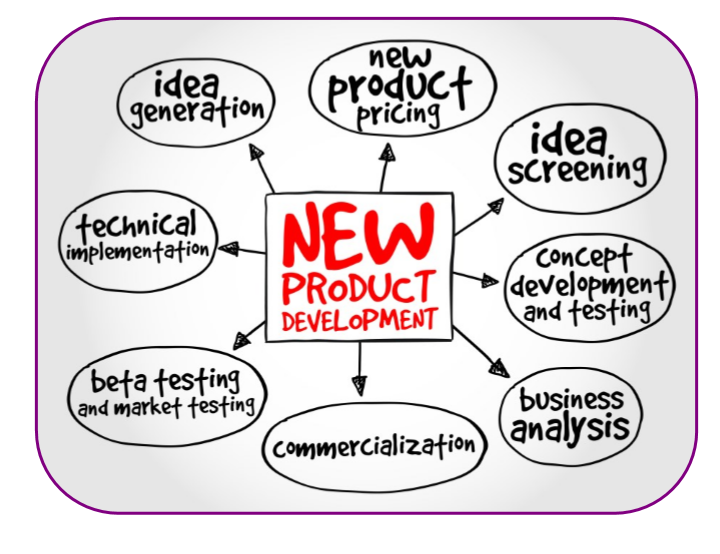

Industrial and Process Engineering

Our Process Engineers focus on the design, operation, control, and optimization of our clients manufacturing process. When developing new systems or optimizing current systems, we incorporate Time Studies, Lean Principles, Quality Operating System disciplines, Failure Modes Effects Analysis (Design and Process), In-Station Process Control, and Total Cost Management. For new products, we have extensive experience with the Design for Manufacturing (DFM) or Design for Assembly (DFA) evaluations to reduce delays as production ramps-up.

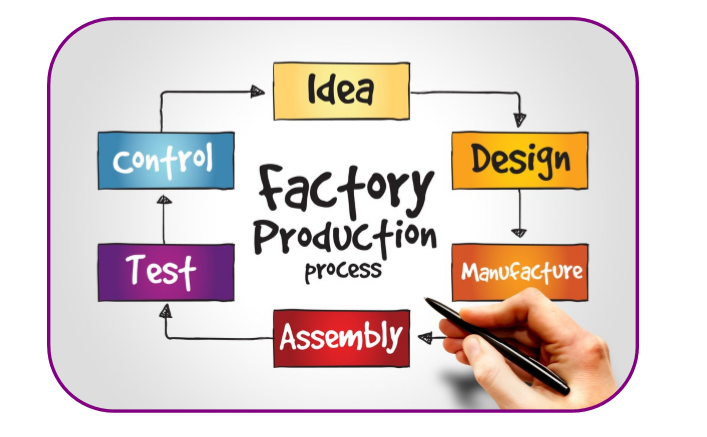

Product Manufacturing

Launch Along with the implementation of APQP and PPAP, we implement a Product Launch Readiness & Validation Strategy. The Launch Preparedness elements include: Product Development, Manufacturing Process Layout, Production Process Validation, Production Capacity, Measurement and Testing, Suppliers & Assembly Parts, Facility & Tooling, Material Planning & Logistics.

Facility & Tooling Layout

Design and develop manufacturing solutions for new facilities and companies undergoing facility changeover due to the incorporation of new products. This includes developing facility requirements, layout of production and material areas, equipment and tooling specifications for sourcing, manufacturing process development, specifying manufacturing systems requirements, and manage the implementation of all aspects of the facility and manufacturing equipment.

Manufacturing Metrics & Tracking Systems

We implement a “Control Plan Methodology” that promotes continuous improvement. We implement process monitoring and statistical methods that will be used to control Supplier, Product, and Customer Quality. The metrics ensure that customer needs and expectations are understood, deployed, and controlled in manufacturing and assembly process. Product, process and inspection standards are established and continually monitored.

Contract Manufacturing

OES can develop and implement a contract manufacturing strategy for our client. We identify and qualify manufacturing partners for a new or existing product. OES will develop Bid and/or Sourcing Specification, and conduct bidding rounds, for the companies to quote the business. The contract manufacturer strategy can be a Total Turn-Key that includes all elements of the Business and Product manufacturing value chain or specific value chain items.